Robotics is continuously changing industry after industry, especially with new technology advancements that take the use of robots beyond the manufacturing industry. The increasing number if demands for robots is encouraging developers to invest in creating robots that can perform various sets of tasks, for a multitude of industries. With businesses facing more and more challenges, such as increasing demands for faster delivery and limited resources, especially skilled employees, the adoption of robotics may be mandatory for them to survive and surpass their competitors. But what does the future predict for the continuously changing and evolving world of robotics?

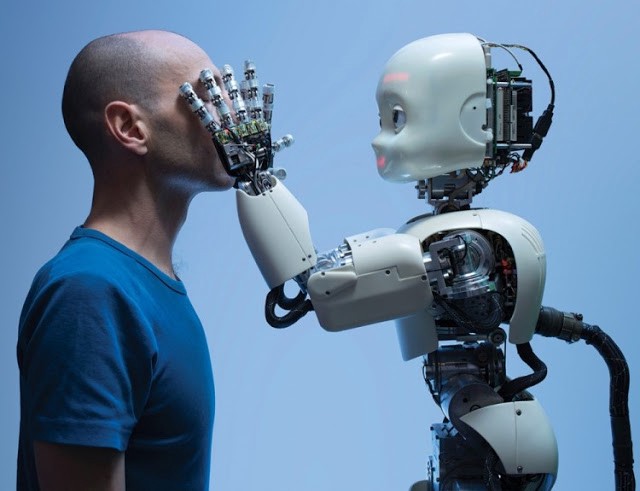

Cobots Are on the Rise

Collaborative robots, or cobots, as they are known in the industry, have taken the spotlight in the last couple of years. The reason behind this is the rapid and cost-effective advancements of artificial intelligence and the multitude of sensors developed to increase the safety of cobots. This is making cobots smarter, more effective and more suited to work alongside humans than ever. The new technologies are enabling cobots to sense the presence of human colleagues and adjust their position to prevent collision, as well as allowing them to be easily trained and redeployed to various environments. Market researches have shown that 2018 was dominated by collaborative robots and it is expected that, by 2020, the number of cobots in use will exceed 150,000. The predictions can’t be more accurate, given the fact that more and more big manufacturing companies, especially in the automotive industry, are embracing the cobot movement. Although the market has grown by more than 60% in the last year, the market still remains challenging, as the number of vendors is increasing more than the demand.

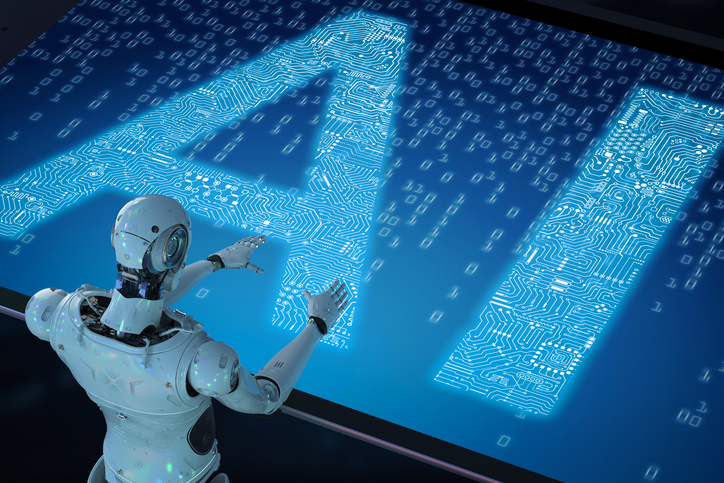

Artificial Intelligence and Robots

As robots and artificial intelligence (AI) have both experienced a massive evolution in the past years, which is why, despite being clearly separated by the industry, they are commonly believed to be one and the same concept. Broadly speaking, robots are machines that can be programmed to execute a specific task. When AI comes into play, the machine is turned into a smart robot that can perform more challenging tasks in difficult environments that can sometimes be too dangerous for humans, such as extreme temperatures or toxic environments. While we are yet to reach the moment when smart robots are able to perform any tasks a human could, what they’re actually exceeding at is performing individual tasks with far more accuracy and rapidity a human could.

Bringing AI and robotics together is no longer breaking news, but with the costs of AI incorporation constantly decreasing, we can expect to see it happening even more than before. Within the last years, integrating AI into robot software has helped in various areas, such as data processing, vision and motion control. Manufacturing companies and warehouses are now using intelligent robots, that have, with the help of AI, learned to identify, grasp and sort items, by being constantly fed information by their human coworkers. Agriculture also seems to be benefiting for the AI-robots fusion, with intelligent robots being able to plant and care for the crops more effectively, reducing both water waste and fertilizing pollution.

Autonomy and Mobility

When talking about mobile autonomy, the first that come to mind are autonomous cars, which have been along for quite some time now and have hit the spotlights in the last couple of years. Big car manufacturers are constantly testing the waters for autonomous cars, but mobile autonomy means much more than that.

Delivery robots seem to be the next big thing, as the shipping industry is facing more and more challenges in securing and delivering extremely fragile packages intact. While some of the robots are specially built to ensure safe delivery in indoor environments, such as warehouses and office floors, others are designed to roam the streets to bring hot food and fresh groceries to people’s doors. One of the issues standing in the way of delivery robots is the road infrastructure, which is not always robot-friendly. Delivery robots are currently being tested in various areas of the world, such as Milton Keynes in UK, Silicon Valley, California, as well as some parts of Phoenix, Arizona. Because of their modern roads and grid-like streets, these areas have turned out to be the perfect place to test such technology.

Robots in the Cloud

Experts predict that by 2020, more than 60% of robots will rely on cloud-based software to develop new skills and cognitive capabilities. Right now, every action performed by a robot demands pre-programmed information and extremely high amounts of processing power. If all of this information was stored on the Cloud, robots could be more cost effective and accessible for both businesses and consumers. This could eventually lead to application marketplaces opening to offer developers a place where they could share and sell their programs that can be integrated into existing robots or used to create new robots altogether.

Robotics as a Service

Probably the newest business model in the robotics industry is Robotics as a Service (RaaS). This essentially means companies are now able to offer robots as a service instead of a product. The robots are offered for rent, thus helping companies avoid big capital investments at the beginning of production, while still benefiting from the advantages of collaborative robots. This has become possible due to the development of extremely intelligent robots that can be reprogrammed to perform various tasks over and over again. The beforementioned Cloud is going to make RaaS even more effective, as it provides access to a multitude of programs that can allow robots to receive tailored information, based on the environment they are performing in and making them even more adaptable. Nowadays, the two industries that benefit the most from using RaaS are manufacturing and healthcare, with manufacturing being the industry that invests the most in robots.

Like any new technology, RaaS still has some challenges to face before turning into a general reality. Cognition, manipulation and interaction are three key elements the robotics industry needs to focus on, to ensure smart machines are able to accompany humans in their daily tasks and challenges.